Petroland sliding vane pumps are specially designed to comply with the pumping requirements demanded by the LPG industry. Bulk delivery of LPG requires the use of heavy duty, reliable equipment and is an important part of every LPG markets. The equipment used in modern bulk trucks must be designed and constructed to perform in a broad spectrucm of operations conditions.

Sliding vane design is ideal for, LPG, butane, propane, freon, fuel, gasoline, DME, anhydrous ammonia, propellants, refrigerants and similar liquefied gases.

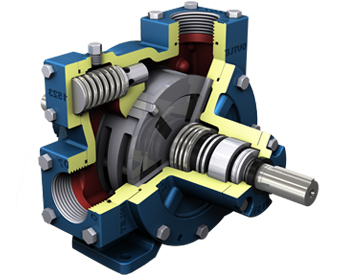

Utilizing unique sliding vane design, these positive displacement pumps offer the best combined characteristics of sustained high level performance, energy efficiency, trouble-free operation and low maintenance cost.

Pump models are available in 1.5" to 4" port sizes. All models have ductile iron construction for thermal shock resistance, low friction ball bearings for high efficiency and quiet operation.

|

Max. Capacity: 65 m3/h

|

||

|

Max. Diffr. Pressure: 8.5 bar

|

||

|

Max. Viscosity: 100 cSt

|

||

|

Temperature Range: -30 0C to +150 0C

|

|

Model

|

Inlet / Outlet Size

|

Capacity

(at 0 bar) |

Max. Speed

(rpm) |

Max. Differential Pressure

|

||

|---|---|---|---|---|---|---|

| LT/1 rev. | GPM/1 rev. |

PSI

|

Bar

|

|||

| PV 150 | DN50 / DN40 | 0.088 | 0.023 |

1750

|

120

|

8.5

|

| PV 200 | DN50 / DN50 | 0.42 | 0.11 |

750

|

||

| PV 220 | DN50 / DN50 | 0.43 | 0.11 | |||

| PV 320 | DN80 / DN50 | 0.6 | 0.15 | |||

| PV 330 | DN80 / DN50 | 0.65 | 0.17 | |||

| PV 350 | DN80 / DN80 | 0.9 | 0.23 | |||

| PV 360 | DN80 / DN80 | 0.89 | 0.23 | |||

| PV 450 | DN100 / DN80 | 1.85 | 0.49 | |||

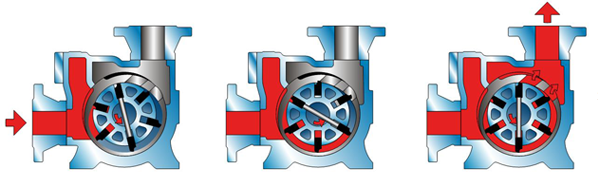

As shown in Figueres, the pumps use a rotor with sliding vanes that draw the liquid in behind each vane, through the inlet port and into the pumping chamber. As the rotor turns, the liquid is transferred between the vanes to the outlet where it is discharged as the pumping chamber is squeezed down. Each vane provides a positive mechanical push to the liquid before it.

Vane contact with the chamber wall is maintained by three forces: