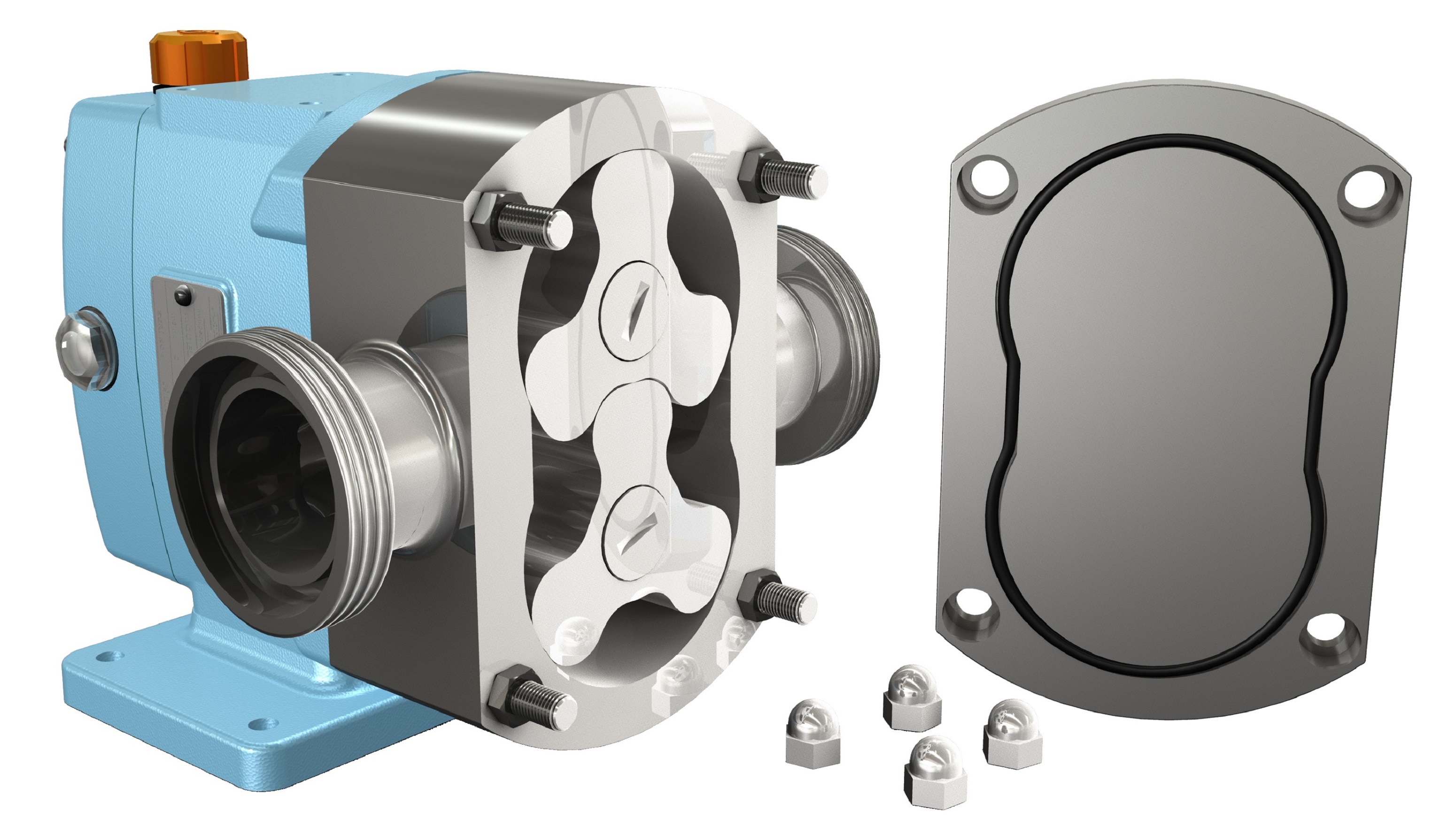

PL series pumps have been specially designed to make dismantling (whether for inspection, cleaning and maintenance) quicker and easier. The forward seal position places the seals in direct contact with CIP fluides. Superior seal cleanlines lengthens seal life and minimizes seal flaking (prodcts contaminations). Because the seals are located directly behind the rotors, areas of product entrapment are eliminated for superior hygienic performance.

PL series pumps have been specially designed to make dismantling (whether for inspection, cleaning and maintenance) quicker and easier. The forward seal position places the seals in direct contact with CIP fluides. Superior seal cleanlines lengthens seal life and minimizes seal flaking (prodcts contaminations). Because the seals are located directly behind the rotors, areas of product entrapment are eliminated for superior hygienic performance. |

Max. Capacity: 100 m³/h

|

||

|

Max. Diffr. Pressure: 20 bar

|

||

|

Max. Viscosity: 440.000 cSt

|

||

|

Temperature Range: 0 to +120 °C

|

|

Model |

Inlet / Outlet Size |

Capacity |

Max. Speed (rpm) |

Max. Diffr. Pressure |

|||

|---|---|---|---|---|---|---|---|

|

mm |

Inch |

lt/1 rev. |

GPM |

PSI |

BAR |

||

|

PL 115 |

15 |

½’’ |

0.02 |

0.53 |

1000 |

290 |

20 |

|

PL 125 |

25 |

1” |

0.05 |

1.32 |

|||

|

PL 140 |

40 |

1 ½’’ |

0.12 |

3.17 |

800 |

175 |

12 |

|

PL 150 |

50 |

2” |

0.21 |

5.54 |

115 |

8 |

|

|

PL 250 |

50 |

2” |

0.4 |

10.81 |

700 |

175 |

12 |

|

PL 265 |

65 |

2 ½’’ |

0.62 |

16.35 |

115 |

8 |

|

|

PL 380 |

80 |

3” |

1.02 |

26.90 |

600 |

175 |

12 |

|

PL 3100 |

100 |

4” |

1.44 |

37.98 |

115 |

8 |

|

|

PL 4100 |

100 |

4” |

2.27 |

59.88 |

500 |

175 |

12 |

|

PL 4125 |

125 |

5” |

3.34 |

88.10 |

115 |

8 |

|