PS series pump is a self-priming side channel pump capable of handling gas along with the medium and operates at low noise level. PS pumps are used for problem free pumping of clean liquids at unfavourable suction side conditions. They are also very suitable for positive suction head (NPSH) belows 0.5m.

Therefore PS pumps provide the most appropriate solutions for liquefied gases, liquids under vapour pressure, refrigerants and especially lpg applications.

Side Channel design fill the hydraulic performance void between positive displacement pumps and centrifugal pumps. Fully open "star" impellers interact with the side channel casing creating an intense of energy to the pumped liquid or liquid / gas mixture. The corresponding pressure increase (pump head) equals 5 to 10 times the amount generated by a similar size cenrtifugal pump at same rpm.

Working Principle

The design of the side channel pump allows for the transfer of liquid-gas mixture with up to 50% vapor. Therefore eliminating possible air of vapor locking that can occur in the other pump designs. A special suction impeller lowers the NPSHr for the pump.

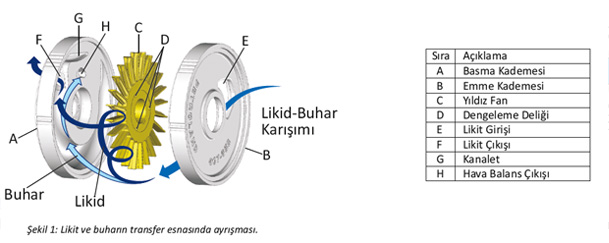

The side channel pump design is similar to a regeneratice turbine in that impeller makes regenerative passes through the liquid. However, the actual design of the impeller and casing as well as the principles of operation differ greatly. The side channel pump has a channel only in the discharge stage casing (A) and a flat surface which is flush with the impeller on the suction stage casing (B). A star shaped impeller (C) is keyed to the shaft and axially balanced through equalization holes (D) in the hub of the impeller.

The liquid or liquid/vapor mixture enters each stage of the pump through the inlet port (E). Once the pump is initially filled with liquid, the pump will provide a siphoning effect at the inlet port. The effect is similar to what happens in water ring pumps. The water remaining in the pump casing forms a type of water ring with a free surface. A venturi effect is created by the rotation of the impeller and the free surface of the water, thus pulling the liquid into the casing

After the liquid is pulled through the inlet port, it is forced to the outer periphery of the impeller blade by centrifugal action. It is through this cenrifugal action that the liquid is accelerated and forced into the side channel. The liquid then flows along the semicircular contour of the side channel from the outer most point to the innermost point unil once again it is acceleratedby the impeller blade.